"Berang" (berang)

"Berang" (berang)

03/30/2019 at 01:37 • Filed to: None

11

11

8

8

"Berang" (berang)

"Berang" (berang)

03/30/2019 at 01:37 • Filed to: None |  11 11

|  8 8 |

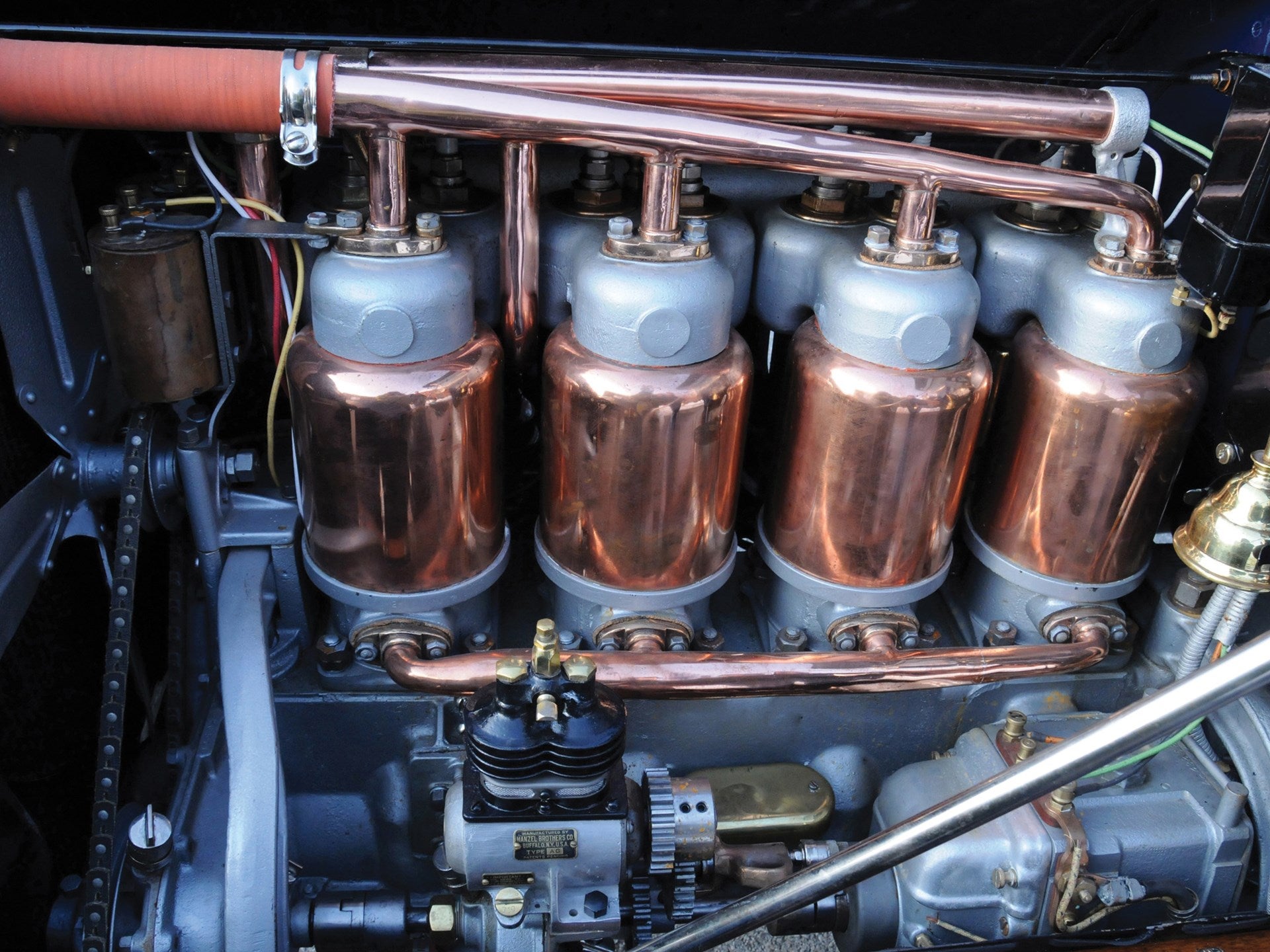

Cadillac’s early cars came equipped with copper water jackets, each cylinder jacketed separately. Must have cost a fortune to make, even in 1908.

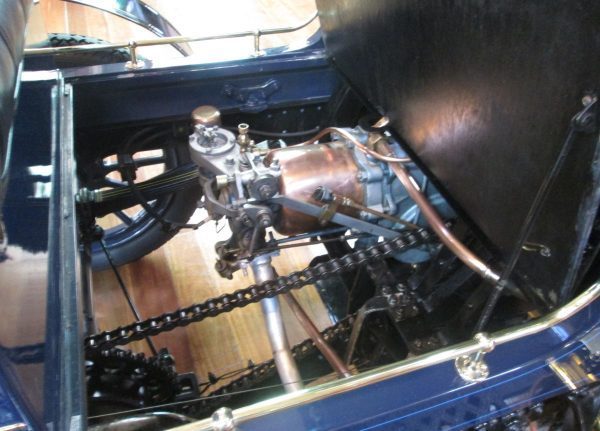

A 1913 model above.

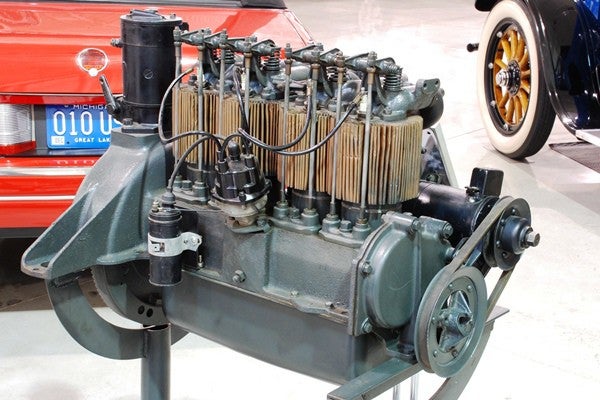

An early single cylinder model.

Nothing looks classier than copper in the engine bay.

Future Heap Owner

> Berang

Future Heap Owner

> Berang

03/30/2019 at 01:43 |

|

*whistles*

gmporschenut also a fan of hondas

> Berang

gmporschenut also a fan of hondas

> Berang

03/30/2019 at 01:53 |

|

the later crazy copper cooled chevy

Berang

> gmporschenut also a fan of hondas

Berang

> gmporschenut also a fan of hondas

03/30/2019 at 02:09 |

|

excessive ingenuity for a problem that had already been solved.

Franklin had been making air cooled cars successfully for over a decade before Chevy screwed it up.

BaconSandwich is tasty.

> Berang

BaconSandwich is tasty.

> Berang

03/30/2019 at 10:02 |

|

Sounds about like Chevy and diesels...

sn4cktimes

> Berang

sn4cktimes

> Berang

03/30/2019 at 12:49 |

|

Was compression just really low? Confused about the strength of the cylinder.

Berang

> sn4cktimes

Berang

> sn4cktimes

03/30/2019 at 13:54 |

|

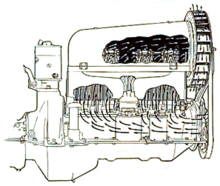

The cylinder itself was cast iron, only the water jacket was copper. You might think of it like an engine with wet liners, where the cylinders are iron/steel but the block is aluminum.

gmporschenut also a fan of hondas

> Berang

gmporschenut also a fan of hondas

> Berang

03/30/2019 at 15:34 |

|

Those franklins were also at a minimum 4 times the cost

Berang

> gmporschenut also a fan of hondas

Berang

> gmporschenut also a fan of hondas

03/30/2019 at 15:59 |

|

I kind of wonder if part of the reason Chevy designed things the way they did, was to get around Franklin patents. The copper fins are actually pretty clever, but if you look at the overall system, including just the direction of the air flow, it makes no sense.

The cooling air passes over the bottom of the cylinders first, not the heads. So the coolest part of the cylinder gets the most cooling. Then the air intake is only inches from where hot air exits the fan. Actual engineers worked on this... they must have seen the problems. I can only guess they had to be working around other patents.